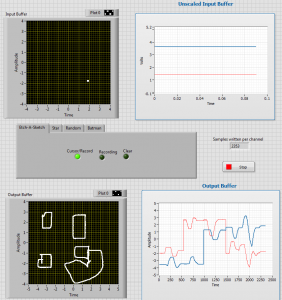

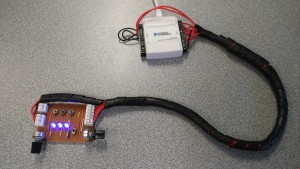

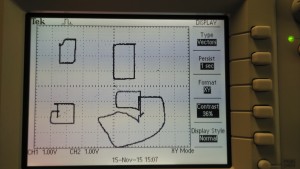

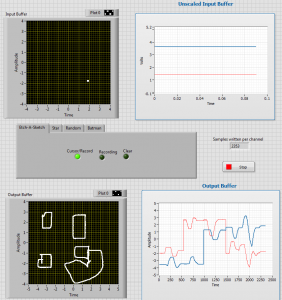

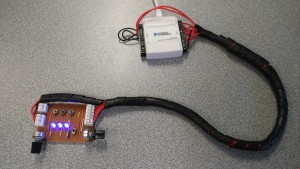

This was an analog data acquisition project,in addition to the extra features shown below there is the usual project sub-site. Continue Reading

This was an analog data acquisition project,in addition to the extra features shown below there is the usual project sub-site. Continue Reading

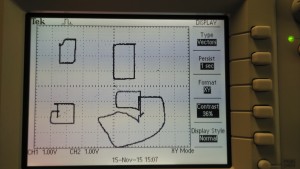

After a crash course on the FORTH programming language, extending the compiler, directly addressing system registers and assembly code we were unleashed to develop our own project in forth.

After a crash course on the FORTH programming language, extending the compiler, directly addressing system registers and assembly code we were unleashed to develop our own project in forth.

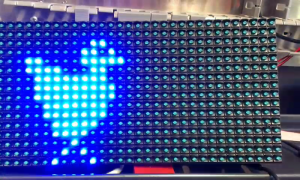

We located a 32 x 16 LED dot matrix display intended for use with an arduino (Link) with basically no hardware documentation and set to work. Dedicated project sub-site here. Continue Reading

New semester, new systems to conquer and new ideas to implement.

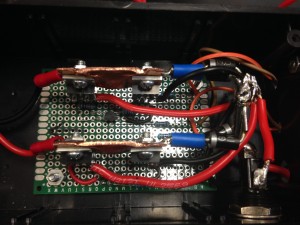

![IMG_0979[1]](https://www.eeadventures.com/motordriver/files/2015/08/IMG_09791-300x225.jpg)

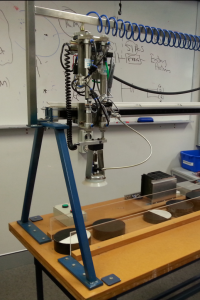

This time my team and I built a motor controller based around a PicAXE micro controller.

The controller featured smoothed control between any two points via a discrete transfer function with zero-crossing cutoff, a choice of either serial communication or voltage controlled set points, and a set of visual indicators showing both the desired set point and the current transfer function values.

Credit to Joseph Eric Roy and Stefanie Schmidiger as group members.

This project also has its own sub-site available here.

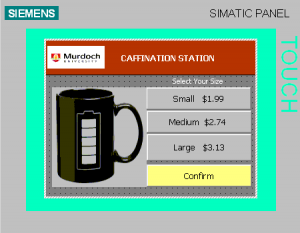

The purpose of this project was to become familiar with the HiGraph (Graphical State Machine) and SCL (Structured Control Language) features within the Siemens S7-300 series PLC.

The purpose of this project was to become familiar with the HiGraph (Graphical State Machine) and SCL (Structured Control Language) features within the Siemens S7-300 series PLC.

We took it upon ourselves to further explore the Human Machine Interface (HMI) capabilities and closely integrate the HMI into the project over a Multi-Point Interface (MPI) network .

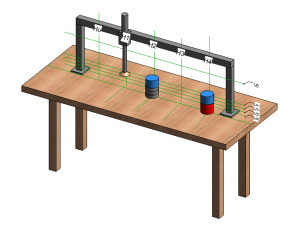

The purpose of this project was to use two standalone Programmable Logic Controllers (PLCs) where one is simulating a process (with artificial noise and disturbances) and the other PLC is acting as a controller. We decided to also include a Human Machine Interface (HMI) to allow the for both monitoring of key information and to adjust/reset the controller parameters. Click Here to be taken to the dedicated sub-site

Within a PLC course, as an introduction, I was required to develop an application for the “Moeller EasySoft PLC”, a rudimentary PLC when compared to current industrial standards. During code development, PLC programming techniques and standards had not been taught beyond the mechanics of ladder logic processing, latching and memory use.

Within a PLC course, as an introduction, I was required to develop an application for the “Moeller EasySoft PLC”, a rudimentary PLC when compared to current industrial standards. During code development, PLC programming techniques and standards had not been taught beyond the mechanics of ladder logic processing, latching and memory use.

This application was widely recognised as the best in the class and the only project to fail-safe on controller power loss, attempt to recover from an error and to have verbose error diagnostics.

Principles of Electronic Instrumentation assessment project, 22% of unit mark.

The brief was to detect if an object passing through two sensors is exceeding a given speed using any of a mandated list of components with minimal power consumption. The of permissible components included infrared LEDs, photo-diodes, NPN BJTs (transistors), 555 timers as well as a selection of resistors and capacitors.

Continue Reading

Principles of Electronic Instrumentation assessment project, 10% of unit mark.

Paraphrased project brief: become familiar with Multi-vibrators and Bipolar Junction Transistors to design a Schmitt trigger to meet the given specifications.

The context given is that a degraded signal was being received by a photo diode (modelled as a current source) and needed to be cleaned up by a Schmitt Trigger utilising hysteresis.

Supply voltage an trigger points were specified by the facilitator. Continue Reading