Overall the system was to be split in to the operations of each PLC, the controller and the simulated process.

Each of the PLCs have a number of tasks which must be performed, the process requires more mathematical and code functions to be implemented where as the controller required more user interaction and intuitive design on the Human Machine Interface (HMI).

Output/Sample Rates

The Control PLC execution rate is to be set at 50ms to allow the PID controller time to operate correctly on the PLC’s CPU.

The Process PLC is not burdened with the controller and will re-evaluate its output every 10ms to produce a more real-time like output.

Controller PLC Functions to be added:

- Tuned PID Controller

- HMI to alter control parameters

- HMI to monitor actions

Process PLC Functions to be added:

- Shift Register

- Process Difference Equation

- First Order System – Disturbance

- Pseudo Random Number / Noise Generator (Variable)

- First Order System – Noise

- Process Summing Point

Low Pass Noise Filter

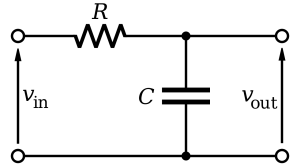

In order to implement a meaningful derivative term a controller with system noise, a first order passive low pass filter was to be constructed and inserted between the system and controller.

As the process’ tau is 1, a cut-off frequency a bit higher than 1 Hz was desired and thought necessary for optimal controller performance.

In this case the noise, after being passed through its own transfer function, is expected to have a relatively close frequency to that of the process which reinforced a need to have the filter output drop relatively early [5].

[1] http://en.wikipedia.org/wiki/Low-pass_filter

Expected Behaviour

Without a controller the system is known to overshoot the desired mark and oscillate around the desired set point. In our process this is unacceptable in such a sensitive environment and must be controlled.

To implement a more effective controller, a derivative term is desired but by design the simulated process will produce noise on its output. This is considered a reality in the real world, to combat the effect of noise a passive first order low pass filter was constructed to remove high frequency noise and aliasing.

It is also expected that the technician will be able to use a Human Machine Interface (HMI) to monitor the process/controller and alter the parameters of or disable the controller as required.

An added benefit of using an RC filter on the process’ output is that some smoothing of the Process’ zero order hold is expected which will more closely resemble a real-time process.